|

前缘送纸电脑全自动圆压圆模切机

收藏

商品说明

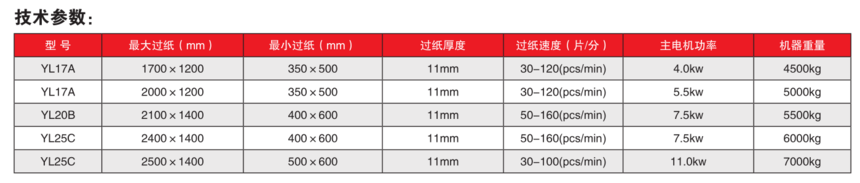

功能特点: ◆ 采用世界先进前缘送纸系统,送纸精度高、速度快、送纸轮寿命长,送纸实现10000张/小时,精度±0.5mm; ◆ 送纸速度实现每小时10000张,模切精度±0.75mm; ◆ 相位采用行星齿轮电动调整,开机停机均快速调整; ◆ 前挡纸板手动调整,侧挡纸板电动调整; ◆ 导纸辊有槽胶面,以防压坏纸板,增加送纸准确性。 ◆ 软辊自动修磨机构提高胶套重复使用率,可修磨3—4次; ◆ 线速度自动补偿确保每一批纸箱的模切尺寸完全一致; ◆ 进口美国CUE聚胺脂胶垫,安装方便,模切1200万次; ◆ 机械式软辊左右横向移动40mm,胶垫磨损均匀; ◆ 六级精磨齿轮采用40cr材质,噪音低,使用寿命长; ◆ 模切辊汽缸式自动分离装置,减少胶套磨损。 ◆ 人机界面,全电脑PLC控制系统; ◆ 主机采用变频调速电机; ◆ 前后控制面板简明集中,操作方便; ◆ 整机由光、电、气联合控制体系; ◆ 整机电器配件均采用品牌厂家产品。 Functional features: It adopts the world advanced leading edge paper feeding system, with high paper feeding accuracy, fast speed and long service life of paper feeding wheel. It can feed 10000 sheets per hour with an accuracy of ± 0.5mm; The paper feeding speed is 10000 sheets per hour, and the die cutting accuracy is ± 0.75mm; Electric adjustment of planetary gear is adopted for phase adjustment, which can be adjusted quickly during startup and shutdown; Manual adjustment of front baffle board and electric adjustment of side baffle board; The guide roller has a grooved rubber surface to prevent crushing the paperboard and increase the accuracy of paper feeding. The soft roll automatic grinding mechanism can improve the reuse rate of rubber sleeve, which can be grinded 3-4 times; The automatic compensation of linear speed ensures that the die cutting size of each batch of cartons is completely consistent; Imported American cue polyurethane pad, easy to install, 12 million times of die cutting; The rubber pad is worn evenly when the mechanical soft roll moves 40 mm laterally; The six stage fine grinding gear is made of 40Cr material with low noise and long service life; The cylinder type automatic separation device of die cutting roller can reduce the wear of rubber sleeve. Human machine interface, full computer PLC control system; The main machine adopts variable frequency speed regulating motor The front and rear control panels are concise and centralized, and easy to operate; The whole machine is controlled by light, electricity and gas; The electrical accessories of the whole machine are made by brand manufacturers. Technical parame

|